Gain Valuable Insights with Reliability and Maintenance Assessments

May 27, 2025

Reliability and maintenance assessments are conducted to improve operational performance by examining changes made to your operations over the years and analyzing how current processes can be optimized. Assessments are designed to identify risks in Overall Equipment Effectiveness (OEE) and critical functions impacting your manufacturing line.

An article in the Journal of Manufacturing Systems informs readers, “Reliability assessment refers to the process of evaluating reliability of components or systems during their lifespan or before their implementation. In the manufacturing industry, the reliability of systems is directly linked to production efficiency, product quality, energy consumption, and other crucial performance indicators.”

With operations teams entrenched in their daily procedures and striving to hit production targets, it’s hard to look beyond short-term fixes and dedicate time to evaluate criticality or identify root causes of systemic issues impacting efficiency and performance.

Imagine an automated manufacturing operation as a dense forest. Each machine, process, and component represent a tree. In the daily grind, manufacturers often focus on individual trees — managing a malfunctioning machine with a quick fix and improving a specific process or quality issue with an ad hoc solution. This approach can be necessary, but it often leads to a narrow view, missing the bigger picture.

“An assessment gives manufacturers a second set of eyes to identify things that potentially may not have been paid attention to. Those who are closest to the issues don’t see the issues.”

Wayne Cosby, Manager of Quality Assurance, Triad Unlimited

Outsourcing your assessment

Reliability and maintenance assessments are often outsourced to third-party contractors like industrial service providers, equipment manufacturers, reliability engineering firms, and risk management consultants. Depending on their services, they can conduct long-term or short-term assessments, offer recommendations, and implement solutions.

Assessments can take a few days to a week to complete onsite, while planning and preparation can take up to several months. Some manufacturers prefer short assessments to identify on-the-surface risks like bottlenecks, obsolescence, and outdated control processes to improve machine performance. Although shorter maintenance assessments require less data allocation and staff participation, they can provide valuable insights and data-driven recommendations to avoid operational disruptions.

You may choose a more comprehensive assessment that requires dedicated organizational involvement to assess risk in all areas of your organization. These areas range from governance and capital planning to operations management and system health. You may require an infrastructure-focused assessment to perform criticality analysis on assets, like roofs or transformers, to see if they risk damaging your manufacturing line and the products going to your customer. Manufacturers may already know the specific operational or procedural challenges they’d like to resolve, which will also determine the length of the assessment.

Depending on the needs of the manufacturer, the process requires some form of resource allocation from staff, whether they are finance teams, plant managers, operators, or technicians. If you’re looking to improve OEE, assessors will recommend that part of the assessment is conducted at the production line while it is operating to discuss process efficiencies with operators and technicians. While planning the assessment with the outsourced party, you can schedule an optimal time for these discussions to avoid disruptions.

If your assessment is focused on analyzing machine components, processes, and performance, assessors have prior conversations with the customer regarding their equipment’s historical information from the original machine builder. This information is comprised of machine layouts, engineering documents, and Bills of Materials (BOMs). Other information will include Standard Operating Procedures (SOPs) and maintenance process records. Documentation on previous installations, redesigns, equipment retrofits, and upgrades is also required. This gives assessors the information they need to formulate effective questions to understand the customer’s pain points. This also lets assessors know if the manufacturer’s information is up to date before they get to the site.

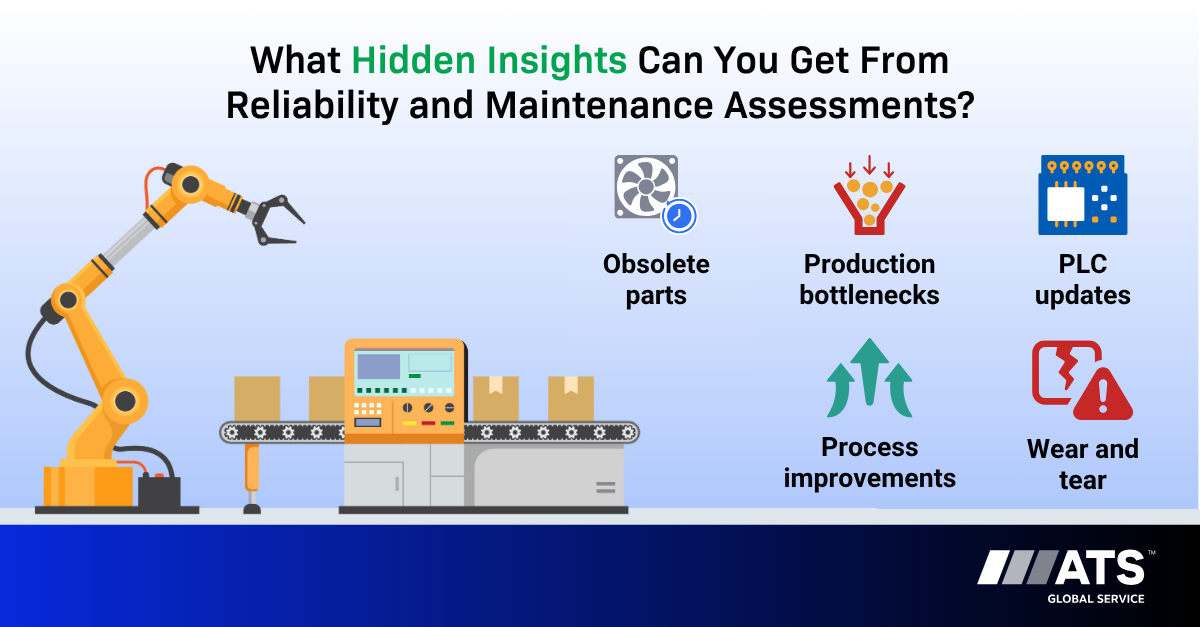

Uncover insights with a reliability and maintenance assessment

Manufacturing production lines can undergo numerous changes over the years and no longer look or perform like the original machinery. Although manufacturers implement new parts and software, many of the original assets remain on the machine.

An assessment can inform manufacturers of outdated assets and maintenance procedures that need to be modified, removed, or replaced, as well as their risk prioritization. With rapidly changing technology, obsolescence in control systems like programmable logic controllers (PLCs) is a major concern for manufacturers with aging systems. Assessors can make recommendations regarding upgrading, operating, and maintaining a new PLC.

“When an assessment identifies obsolescence issues, you can continuously improve your operation by planning to replace obsolete parts to keep the machine at peak performance and avoid unplanned downtime.”

Rajiv Daljeet, Account Manager, ATS Global Service

An assessment can also reveal bottlenecks such as cylinders not operating as effectively as when they were originally programmed. Assessors can make recommendations to fine-tune the efficiency of these components. When manufacturers participate in reliability and maintenance assessments, they may also consider broader operational recommendations for continuous improvement, such as enhancing employee training and maintenance processes, and digitizing SOPs.

Reliability and maintenance assessments give critical insights regarding efficiencies like where it makes sense to automate manual tasks like adjusting guide rollers to widen conveyors. Implementing automation can free up a technician’s time for other critical tasks or projects within the facility. Assessments can also help with recommendations on feeders and other areas on the line where parts are being loaded. Assessors provide recommendations like replacing older hydraulic or pneumatic technologies with newer servo motors to enhance efficiency. Other insights involve how raw materials are handled at the beginning of the line, cylinder cycle time delays, work process efficiencies, and identifying general wear, tear, and deficiencies.

Insights regarding stations not running as fast as others can help pinpoint areas for further investigation and investment. Reliability assessors look at Site Acceptance Tests (SATs) to determine the original state of the station, whether downtime events led to this slowness, or if proper repairs were implemented during machine breakdowns. An assessment of infrastructure-related assets can identify their remaining useful life, when a replacement is required, and whether standard processes are in place to document this information. Other benefits include recommendations to prioritize asset replacement based on criticality for long-term capital investments.

Walking the manufacturing line

Assessments work best when there is a diversity of expertise and experience represented on the project team. On the customer side, it is essential to involve production, operation, engineering, and plant managers. It is also important that Line and IT controls subject matter experts (SMEs), operators, and technicians participate so assessors can get an understanding of everyday tasks required to operate the line. Assessors comprise the project manager, reliability engineer, and system SMEs to gain insight into the machine’s functionality and identify any potential design, retrofit, automation and maintenance improvements.

To do this, a scheduled site introduction and Gemba walk allow assessors to get an in-depth understanding of your manufacturing operation. Involving staff who directly impact the functioning of your line will enhance the quality and thoroughness of the assessment.

An article from Six Sigma Daily advises, “This in-person observation allows leaders to see the difference between what they assumed is happening and what is happening. It also gives them a chance to interact with the people doing the job and see exactly where it is done, as opposed to imagining it from a far-away conference room.”

A Gemba walk can be better conducted while your line is running. In comparison with sitting in a room, the walk enables conversations with technicians and operators, allowing assessors to validate any issues.

Wayne Cosby describes his experience with Gemba walks: “The walk gives people a chance to meet operators, maintenance technicians, and anyone that may be walking by and is involved in the line process. We ask them for their feedback and observations of what they’ve seen.”

Closing thoughts

Reliability and maintenance assessments are integral for continuous improvement over the lifecycle of your automated manufacturing system and operations. Assessments can help manufacturers take control by consistently hitting sales targets with reliability rooted in the production process. With dependable performance data, manufacturers can consider other refinements to their forecasting strategies and inventory management planning.

As a reliable manufacturer fulfilling your orders, consider new opportunities for increasing customer retention and lifelong partnerships. By seeing the forest for the trees, manufacturers can make more informed decisions, prioritize resources effectively, and implement strategies that enhance the overall health and productivity of the entire operation. This comprehensive perspective ensures that manufacturers aren’t just reacting to immediate problems but are proactively improving the reliability and efficiency of their manufacturing ecosystem.

Read our blog to explore a holistic approach to reliability and maintenance assessments and their broader framework and implications for manufacturers.

Sources:

Friederich, J., and Lazarova-Molnar, S. “Reliability assessment of manufacturing systems: A comprehensive overview, challenges and opportunities.” Journal of Manufacturing Systems, no. 72 (2024): 38-58.

“What is a Gemba Walk and why is it important?” Six Sigma Daily. 2018.