- Medical devices

- Pharmaceuticals

- Radiopharmaceuticals

- Chemicals

Automation

performance

experts

ATS Global Service is an industrial services provider that helps manufacturers control operating costs, reduce unplanned downtime, and maintain optimal performance over the lifecycle of their industrial automation systems.

Our goal is to ensure exceptional customer value by maintaining the highest level of asset performance over the entire lifecycle of the installed equipment, regardless of manufacturer.

Higher sustained performance equals better ROI

ATS Global Service partners with manufacturers to ensure that operational and financial goals are realized over the course of their assets’ lifecycle.

We help to seamlessly integrate connected assets into automated processes to manage operations, and optimize productivity and machine performance through asset management, spare parts availability, asset upgrades, and retrofits.

Global service, local presence

45+

years of experience

65+

manufacturing facilities and service centers

550+

team members worldwide

200+

service professionals with an average of 10+ years domain expertise

25+

Fortune 500 companies served per year

~250

customers served per year

Machine builder DNA

ATS Global Service is a subsidiary of ATS Corporation, a decentralized global automation and technology solutions provider to many of the world’s most successful companies.

We bring together experience, skills, and technologies from across ATS Corporation companies to provide the solutions and services to advance manufacturing.

We are unparalleled in our knowledge of ATS equipment and bring that expertise to the rest of your line so that it runs as well as your ATS assets.

Markets served

Life sciences

Transportation

- EV / Hybrid

- Automotive

- Aerospace

Energy

- Nuclear

- Clean energy

Food & beverage

- Produce processing

- Sorting & inspection

- Beverage processing & filling

Consumer products

- Warehouse automation

- Personal care

- Cosmetics

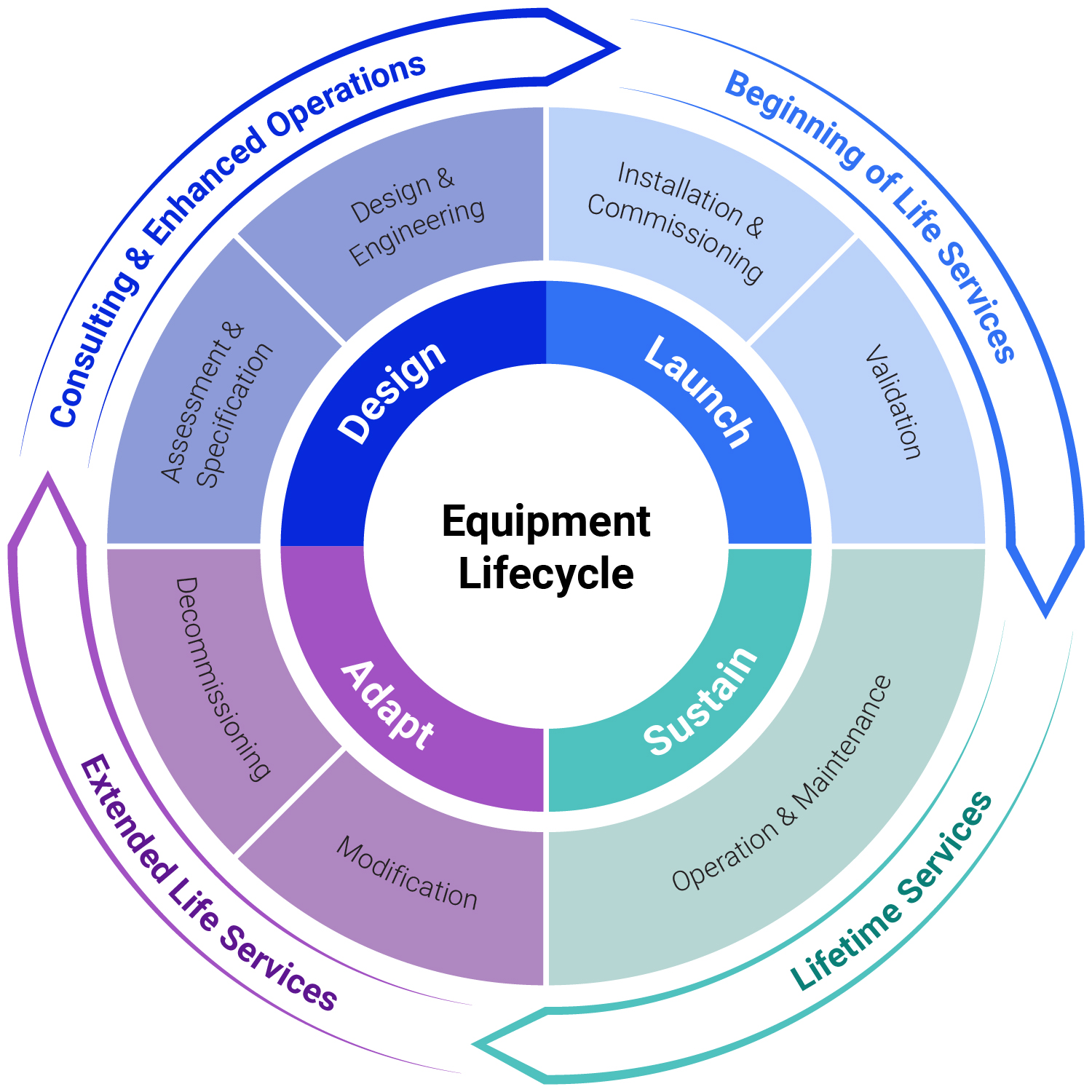

Your lifecycle service partner

From ramp-up to decommissioning, ATS Global Service has solutions and technologies that are designed to help predict, identify, and resolve issues before they happen.

Our capabilities

Asset management

- Installation

- Production Performance

- Reliability and Maintenance

- Training

- On-site / Remote Support

Spare parts

- Replenishment

- Recommended Spare Parts

- Spares Management

Upgrades

- System Upgrades

- Retrofits

- Line Moves

Digitalization

- Collection and analysis of production performance data

- Machine condition monitoring

- Remote-enabled, software-assisted services

Service plans

- Proactive support to maximize the operating efficiency of your equipment