Sustain manufacturing system

performance with data-driven decisions.

Illuminate™ Manufacturing Intelligence

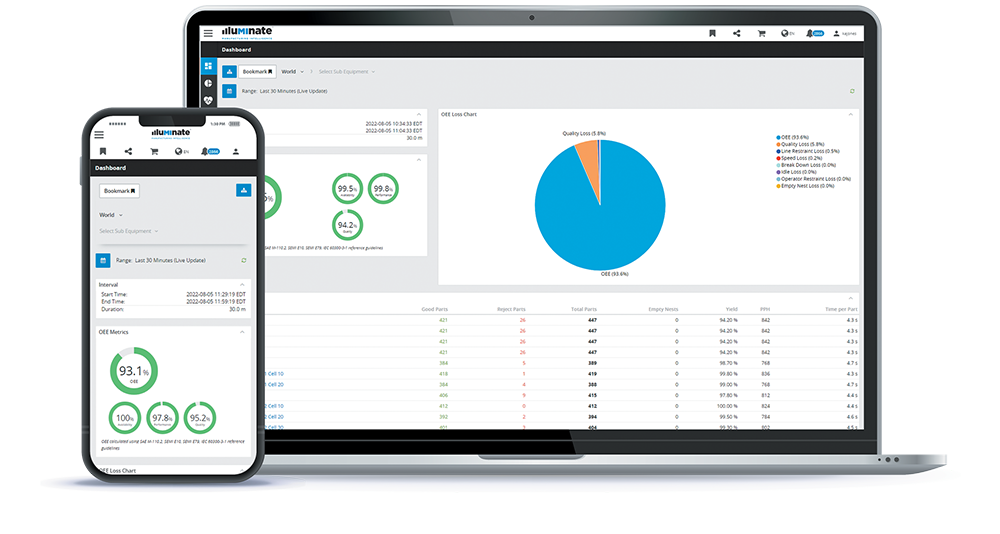

Illuminate™ Manufacturing Intelligence is a production performance monitoring system that simplifies the collection and analysis of data from automated manufacturing systems. With Illuminate software installed, your operations and maintenance personnel can quickly understand what is going on and prioritize actions.

ATS machines are built for serviceability and equipped with Illuminate software to accelerate ramp-up. Once steady-state, production operations are achieved, Illuminate software delivers data-driven insights to uncover opportunities for improvement, leading to significant gains in operational efficiency.

Customer Story

Illuminate Software Boosts Asset Performance by 30% at Siemens Facility

Siemens Electronics Works in Amberg, Germany is using Illuminate software to improve production efficiency, quality, and output with real-time monitoring and data collection.

By identifying bottlenecks and resolving disruptions using Illuminate software, Siemens routinely improves the performance of newly installed automated manufacturing systems by 30% within the first 12 months of operation.

Discover how digital technologies, like Illuminate software, help manufacturers maintain and optimize their automated manufacturing systems and improve operational efficiency.

Visibility into your equipment’s performance

Diagnose and make OEE better

Anticipate component degradation to head off stoppages

Identify and prioritize potential issues sooner

Capture availability and minimize unplanned downtime

Eliminate rejects causing most scrap & energy waste

Determine why and where to more effectively increase throughput

Empower your operations team

Plant manager

Maintenance

Engineer

Operator

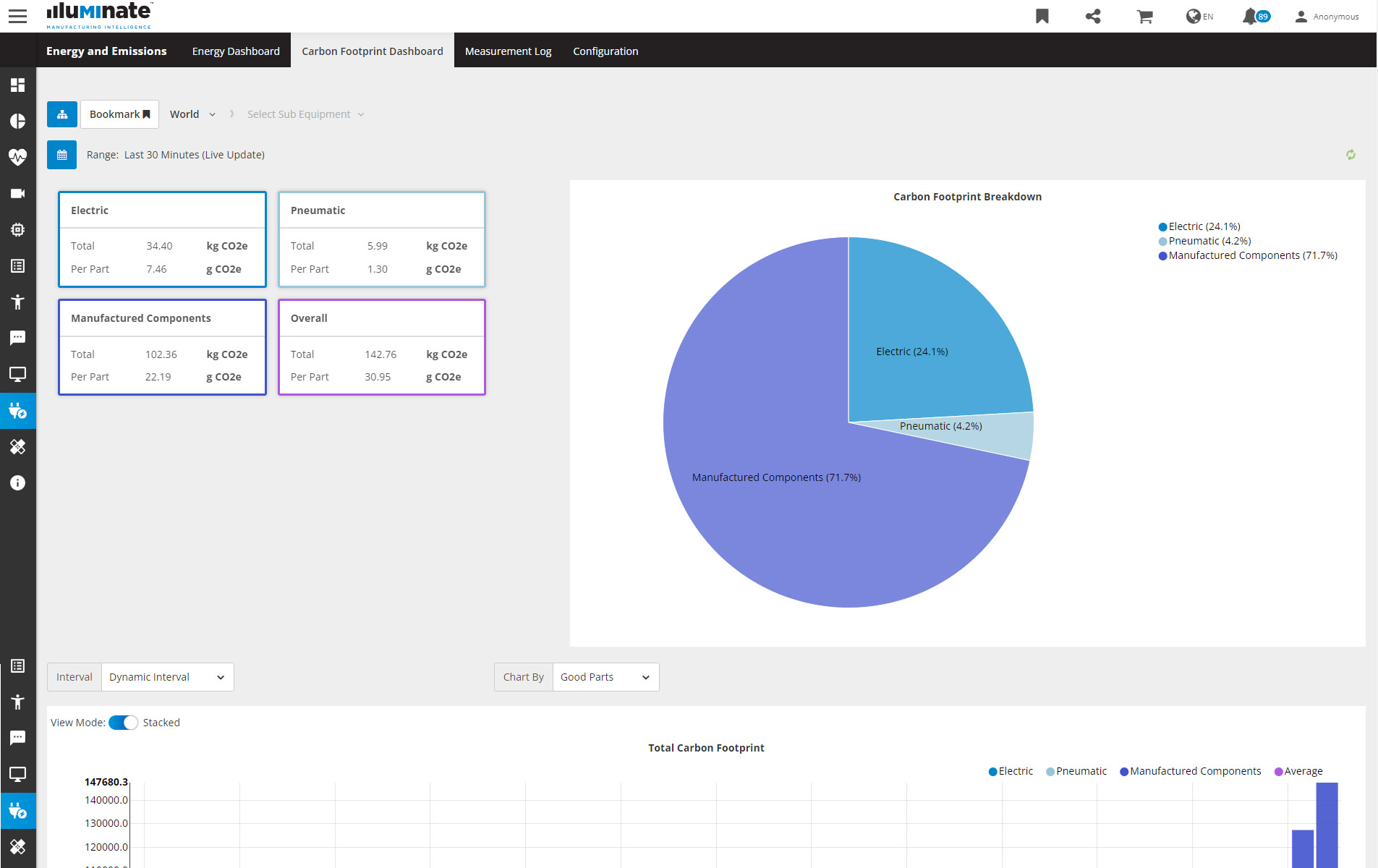

Monitor energy per part to calculate carbon footprint

For ATS machines equipped with electrical and pneumatic metering and the Illuminate™ Energy and Emissions Add-on Module delivers energy and carbon footprint summaries with total and per part energy and CO2 equivalent consumption information.

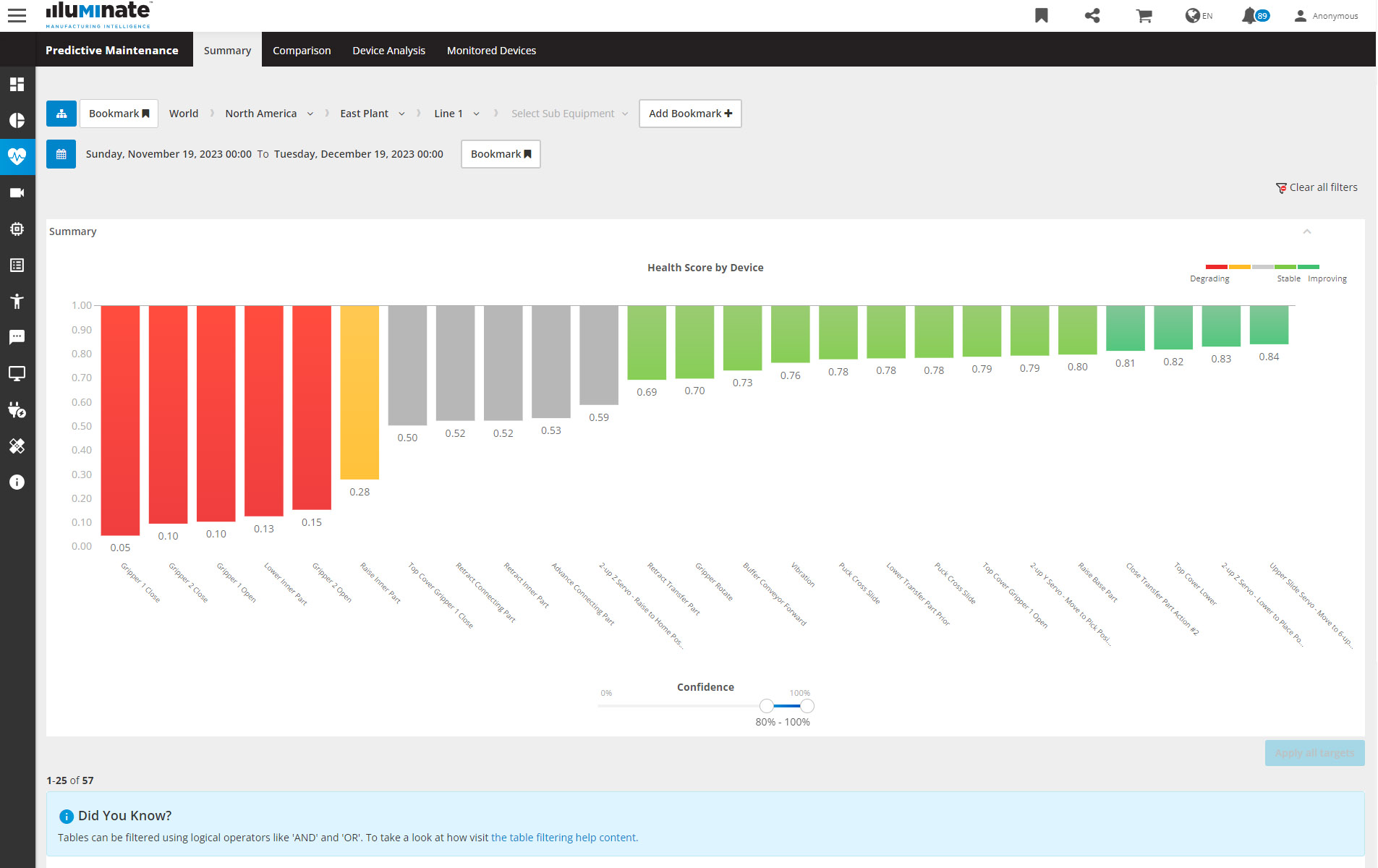

Isolate equipment behavior anomalies

The Illuminate™ Predictive Maintenance Add-on Module analyzes device cycle time data, identifies patterns, and assigns a device level health score to assist in isolating equipment behavior anomalies.

Health scoring flags suspect devices exhibiting changes in frequency or performance so repair actions can be taken to address and pre-empt unnecessary downtime.

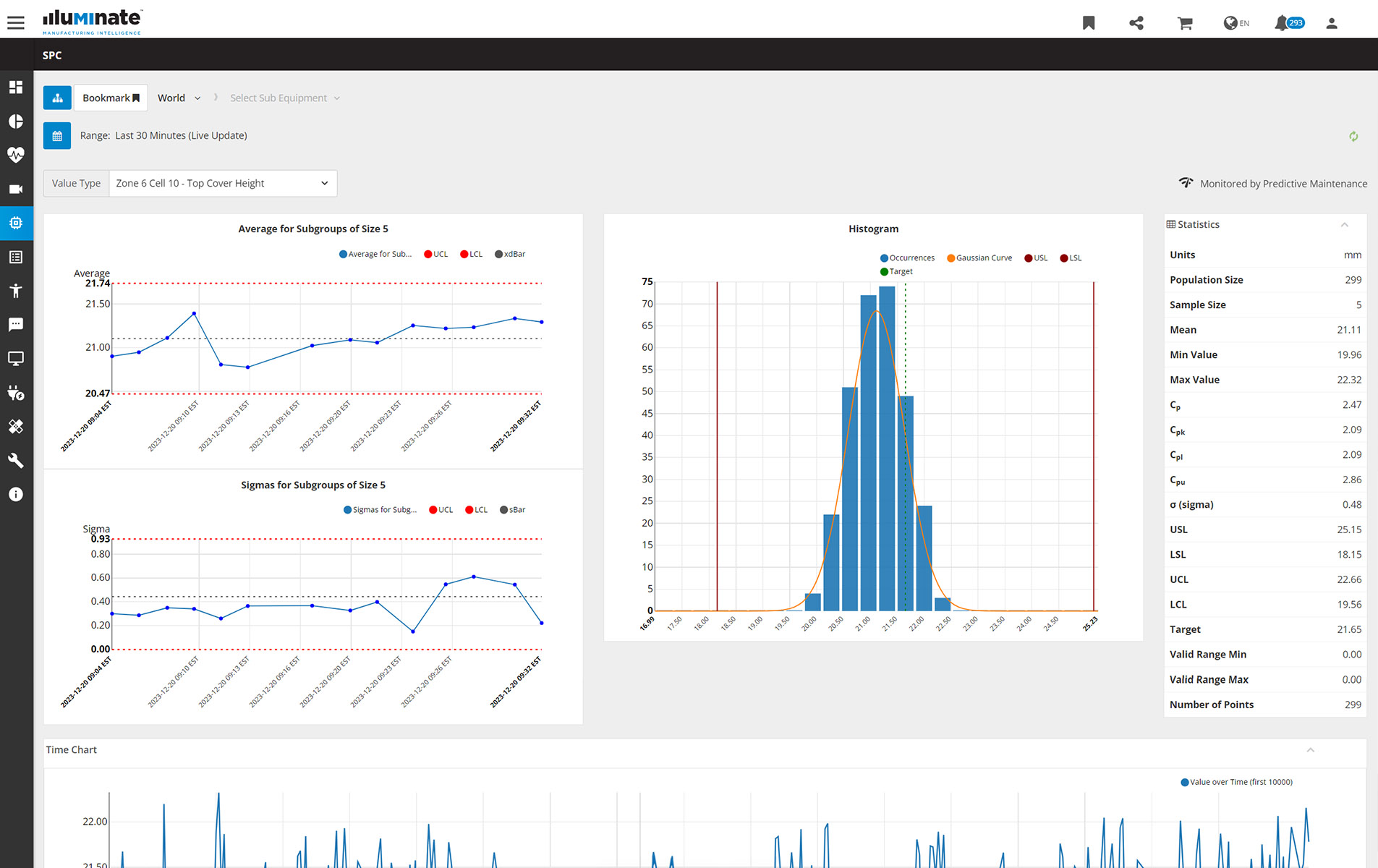

Generate SPC charts on demand, over any time range, for any machine

The Illuminate™ Statistical Process Control (SPC) Add-on Module is a value logging function that tracks specific equipment measurement data, processes statistical calculations including Cp, Cpk, Mean, Minimum, and Maximum values, and then allows for display of variances between carriers or nests.

React faster to production issues

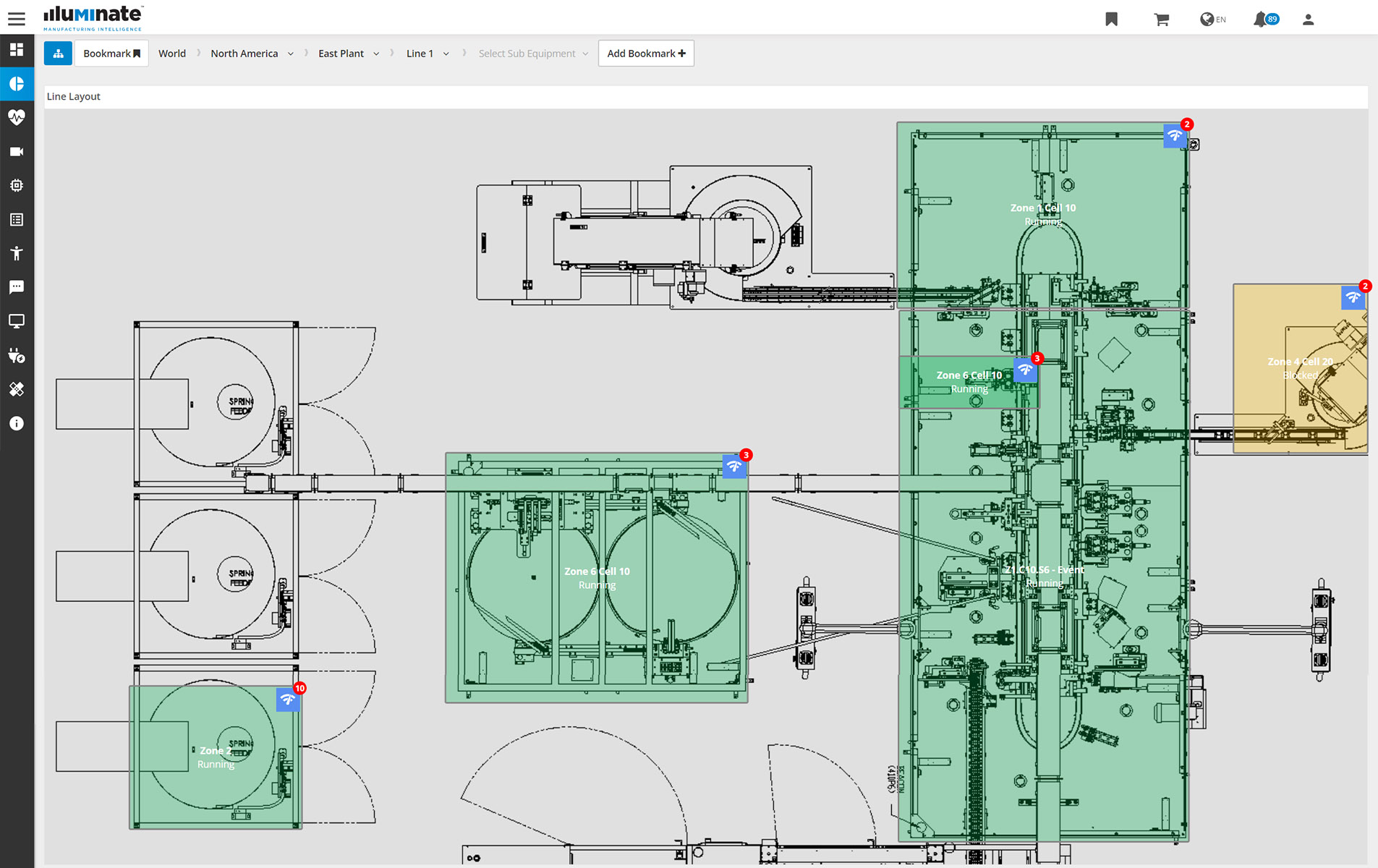

Plant floor diagram in the optional Illuminate™ Interactive Line Layout depicts real-time status of every machine or cell in your line and its upstream and downstream effect.

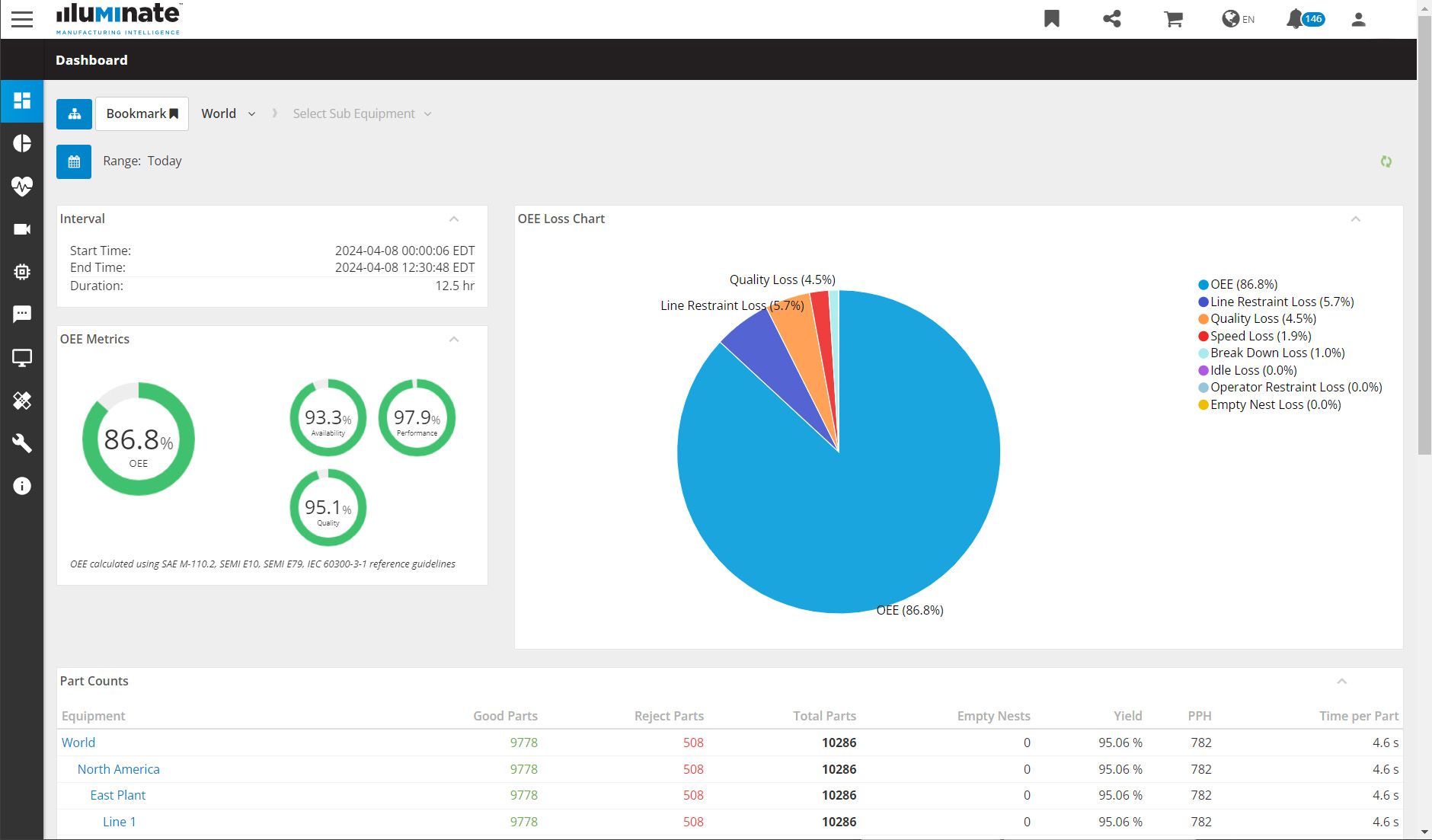

Performance Analysis

The purpose of the Illuminate™ Performance Analysis Module is to help users diagnose and make OEE better.

Simply put, it’s a problem-solving tool that boils the complexity down into an intuitive very easy to use interface. Illuminate software is essential for our ATS machine builders to fine tune the machine before delivery to our customers and then it remains with the machine throughout its life.

Once onsite, the Illuminate Performance Analysis Module provides reports and notifies customer’s operations and maintenance teams so they can respond to issues quickly, unlock hidden performance, and make continuous improvements. Knowing where and why events occur along with successive layers of detail is key to informing decisions. It pinpoints where to focus efforts to reduce downtime, realize OEE gains, maximize line throughput, and improve product quality.

Add-on modules

Standard integrated add-on modules extend the Illuminate Performance Analysis base module functionality.

Production

Energy & Emissions

Monitor energy per part to calculate carbon footprint

Debug Solutions

Event-triggered video capture for automation system troubleshooting

Overhead Display

Full-screen at-a-glance views facilitate quick responses

Manual Station

Enables operator-based processing to be seamlessly integrated into OEE

Quality

Part Traceability

For a serialized complete part history and birth record

Statistical Process Control (SPC)

Generate SPC charts on demand, over any time range, for any machine

Maintenance

Insights

Analytics with actionable intelligence

Predictive Maintenance

Assists in isolating equipment behavior anomalies

Want to extend the capabilities of your Illuminate software?

- Gain visibility across an entire manufacturing facility or plant through the seamless integration of additional machines

- Address specific requirements using add-ons, such as integrating operator-based processing data into OEE with manual stations or measuring energy and CO2 on a per-part or entire line

- Graphically depict equipment, status, and activities with interactive plant diagrams and overhead displays for quicker response

- Receive notifications about emerging trends and production reports directly in your email inbox by linking your system to an SMTP server

- Consolidate production performance data from multiple machines onto a unified virtual machine running Illuminate software