Is Your Asset Management Program in the Danger Zone?

Feb 16, 2024

Drawing upon more than 40 years of experience in Plant Engineering and Maintenance, I want to share the vital insights gained in the realm of Lifecycle Asset Management. I have spent ample time in the Engineering and Maintenance arena, undertaking various site-level and global responsibilities for plant infrastructure.

My Leadership for Reliability imperative occurred early in my career when the site I worked at struggled to meet the global demand for a life-saving pediatric vaccine partly due to issues with infrastructure capacity and reliability. It was then that I embarked on a campaign to engage the entire site organization to recognize that total participation was imperative for achieving our mission-critical objectives.

A site infrastructure system does not materialize overnight and is typically the culmination of previous capital investments that were turned over to site operations. Every asset that comprises this infrastructure can be described according to its system boundary, and I will refer to these boundaries as Facilities, Utilities, and Processes. We all recognize that this asset population can range in the tens of thousands and that these assets, their components, and sub-components all have an inherent risk profile. For example, roofs can have a membrane that will leak if pierced or a piping circuit can leak if the flanges are not torqued correctly or an impeller can fail if subject to cavitation, etc. Every asset has associated failure modes that represent inherent risk and our objective as asset management professionals is to address these risks based on likelihood, severity, and impact.

Often, the Original Equipment Manufacturer (OEM) identifies these inherent risks and offers suggestions to address them through Operations and Maintenance manuals. Based on our unique operating context, asset prioritization, or criticality groupings, we may have elected to perform Failure Mode and Effect Analysis (FMEA). Ideally, our asset management program has evolved to include appropriate operating, monitoring, and maintenance procedures that effectively address inherent risks across our asset base, resulting in acceptable levels of “residual risk.”

Nearly fifteen years ago, I transitioned from the industry to professional consulting, where I participated in numerous asset management program assessments, totaling several hundreds. The assessments were conducted to determine the program maturity level with ranges progressing from Innocent, Aware, Developing, Competent, and Optimizing to Excellent as per the ISO 55000 maturity continuum.

The assessments permitted sufficient opportunities to review asset management systems, data, job plans, inventory, organization structure, and performance measures, including management controls and reporting systems. What was striking was the number of programs that were at the levels of Aware and Developing. That has become a driving force for communicating the critical importance of Leadership for Reliability.

Why does measuring and addressing residual risk matter?

In my exploration of Leadership for Reliability, I’ve emphasized the importance of advancing your asset management program. A key objective for your program evolution is that the appropriate operating, monitoring, and maintenance procedures exist to address inherent risks across your asset base; such that the remaining or “residual risk” is now at an acceptable level. Therefore, the ability to quantify residual risk is a prerequisite to developing a risk mitigation plan.

Leveraging existing asset management practices always seems like a good idea to me as it oftentimes accelerates the transformation process required to meet stated objectives. In the case of measuring residual risk, Triad Unlimited built upon the State of Good Repair (SGR) analysis method that has been employed by the transit industry to identify and prioritize the recapitalization of their infrastructure.

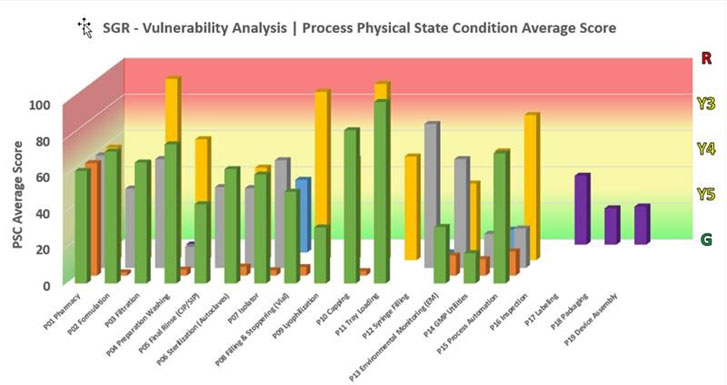

An initial step in the SGR process is to review the master asset list and categorize the assets according to their boundary location which are Facilities, Utilities, and Process. Next, the asset history is analyzed, considering various factors such as installation date, MTBF (mean time between failure), MTTR (mean time to repair), work order count, work order type, and MRO spend, with a focus on the past five years. In addition to collecting this information, it is also important to consider useful life expectancies, obsolescence, and single point of failure status. Each of the aforementioned can be used to develop composite scoring according to a simplistic scale. The results of this State of Good Repair vulnerability analysis illustrate your asset infrastructure’s residual risk level.

The residual risks can be illustrated as Red, Yellow, and Green. I prioritize the Reds to be addressed by the Long-Term Capital Plan as Year 1 and Year 2 projects coupled with a maintenance strategy optimization campaign until such time the replacement asset is operational. The Yellow status is next on the prioritization schedule and is typically addressed in Years 3 through 5. Green reflects those assets that can be addressed beyond Year 5.

An important consideration is to understand how our existing asset base arrived at its current physical state condition or state of good repair. After all, we want our asset management program to minimize our total cost of ownership while achieving or exceeding useful life expectancies. Any deficiencies within our asset management program needs to be addressed such that we protect our capital investments.

Big Picture impact of asset management

Leadership for Reliability requires a broad understanding of the interdependency and the cause-and-effect cycle of both your operating expense and capital investment strategies. I refer to this as the Big Picture strategy for achieving a robust and sustainable asset management program.

A practical approach to challenging the status quo and gaining the necessary support for improving the asset management program is to apply the DMAIC (Define, Measure, Analyze, Improve, Control) methodology. As previously mentioned, we discussed the maintenance maturity continuum that has been defined within the ISO 55000 standard. Measuring your program maturity and residual risk are the necessary prerequisites for analyzing both your Capital and Operating investment strategies. The improvements to be implemented via a prioritized project plan represents your asset management roadmap. Leadership requires knowing where you are now as well as where you need to take the organization next. This is the Big Picture impact.

Where do we go from here?

I have addressed the reliability imperative for quantifying residual risk that resides within both your physical asset infrastructure and asset management program. I also described the Big Picture interdependencies of your operating investment (maintenance program) and capital investment (replenishment program). The Big Picture illustration previously referenced operating expense related to maintenance and baseline capital spend related to infrastructure replenishment, both expressed as a percentage of your site’s Replacement Asset Value (RAV).

I would like to emphasize the importance of an economic performance metric that is referred to as E1 within the European Standard EN 15341: Maintenance Key Performance Indicators. E1 should be considered your asset management program speedometer as it can provide an initial readout as to whether your maintenance program is in an under or overspend scenario. A similar approach can be applied to your re-capitalization rate expressed as a percentage of RAV. I have found the correlation of E1 and re-capitalization rates to the maintenance maturity score of tremendous value for developing the business case and gaining endorsement from senior leadership for supporting an asset management program refresh.

If maintaining the status quo of your asset management program is no longer a viable option, then you will want to develop a comprehensive business case that maps the benefits of targeted asset management program improvements directly to your organization’s stated business objectives. I refer to this as Benefits Realization Planning such that the true potential of asset management is recognized by the entire organization by addressing “What’s in it for me?”

Leadership for Reliability requires a quantitative analysis of the current state of your holistic asset management program. An Asset Management Program and State of Good Repair analysis will provide the basis for determining your current state. Leadership will be necessary to determine the future state and roadmap for benefits realization.

Triad Unlimited offers services such as Asset Management Gap Analysis/Improvement Plan (AMGAIP) and State of Good Repair Analyses (SGR) to help you to quantify residual risk and prioritize asset management strategies effectively.