Lifecycle services

More than maintenance

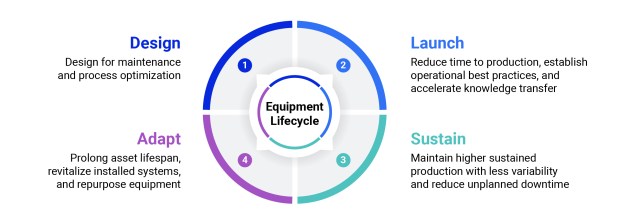

Lifecycle management at ATS is more than maintenance on machines; it’s about bringing together the right experts, technology and process. These three factors work together to build a complete solution for your machine to optimize overall equipment effectiveness (OEE).

ATS has the tools and skillset to do more than mitigate downtime with preventive maintenance; the solution includes looking at the health of how all of your systems run together to optimize your maintenance plan and take you from reactive to proactive.

Maintenance of your assets should be unique to the dynamic nature of your business. We bring a mix of core competencies to evaluate your production as a whole and solve the root problem to maximize your output needs.

Production Service Plan

ATS Production Service Plans are comprised of post-automation lifecycle services designed to help manufacturers meet daily production targets and improve specific aspects of overall operational performance such as safety, quality, delivery, and cost.

Support

Support

Access to ATS experts and customer portal to manage and monitor your service needs.

Customer Portal

Remote Support

Embedded Support

Onsite Emergency Response & Coverage

360° view of service history and asset information

Provides 24/7 web access to request and track service support tickets, verify part order status, and lookup asset information such as recommended part list, part drawings, Bill of Materials (BOM), Operation and Maintenance Manual (OMM) and more.

Benefits

- Improved access to ATS support personnel

- Centralized location for asset information

- ATS Knowledgebase

- ATS eCommerce storefront

Accelerate recovery from downtime events with ATS expert support

ATS support provided remotely via Augmented Reality (AR) technology and/or a secure remote access solution. These tools allow an ATS Subject Matter Expert (SME) to visually inspect the line from the perspective of an onsite technician so they can diagnose issues and provide live assistance.

An ATS SME will attempt to remedy the issue, guide onsite personnel through resolution, and identify its current state in real-time.

Benefits

- Can eliminate need to mobilize an ATS field service technician, thereby reducing the time and expense required to complete critical maintenance tasks and repairs

- No specialized equipment is required, range of devices supported (e.g. PC, Mobile, Tablet or Smart Glasses)

ATS as an extension of the production team

ATS resources onsite for extended production support. ATS resources operate as an extension of the maintenance and/or operations team to sustain optimal machine performance and reduce downtime.

Benefits

- Resources are specialists with the skills and knowledge required to diagnose and resolve issues on the plant floor

- ATS resource will work alongside the in-house maintenance and/or operations team to facilitate optimal knowledge transfer

ATS onsite support during critical events

Onsite technical support that falls outside of warranty and/or an annual service contract, purchased on an ad-hoc basis.

Benefits

- Resources are specialists with the skills and knowledge required to diagnose and resolve issues on the plant floor

Maintenance

Maintenance

Routine and targeted maintenance to lower operating costs and improve the health and performance of automation systems.

System Health Check

PPM Plan Optimization

Machine inspection and preventive maintenance

Periodic verification of line operations, system calibration, and execution of scheduled maintenance tasks per Operation and Maintenance Manual (OMM) completed by ATS service technician.

Benefits

- Higher equipment availability

- Lower direct maintenance cost

- Less unplanned downtime

- Targeted maintenance visits

Maintenance planning and production optimization

ATS Reliability Engineering will develop a risk-based maintenance program to optimize maintenance effectiveness and maximize the operational performance of the assets in scope.

The goals of the maintenance program are to keep assets healthy and operating within the original design specifications to maximize asset availability, production throughput, and quality yield.

Benefits

- Reduction in planned and unplanned downtime

- Improved utilization of maintenance personnel with targeted work plans

Spare Parts

Spare Parts

Build and maintain spare parts inventory, maximize system uptime and control costs.

Spare parts allotment

eCommerce

Review of Asset BOM & Lifecycle

Spare Parts Inventory

Increased parts availability

Spare Parts Allotment of allocated funds held in reserve for spare parts replenishment as needed.

Benefits

- Single point of contact and competitive pricing for launch kits, replenishment inventories, and time-critical replacements

- Lower operational risk by purchasing original ATS parts that have been factory tested and inspected

- Reduce part acquisition time

- Ongoing spares replenishment can be purchased through ATS eCommerce

ATS Genuine parts on demand

Original spare parts maintain the performance of ATS equipment and manufacturing operations, ensuring safety and reliability while helping to minimize downtime and maximize productivity.

Benefits

- Self-service convenience, ATS eCommerce storefront is available 24/7

- Easy to find and order parts using built in tools like predictive search and part visualizations

- Recommended spare parts lists

Proactive identification of obsolescence risks

The component parts within an automated manufacturing system are subject to independent lifecycle management by the vendor. The earlier an obsolescence risk can be identified, the more time available to develop a range of mitigation strategies ensuring equipment availability is maintained.

Benefits

- Maintain updated BOM and drawings

- Reduce risk of stockouts due to obsolete parts

Identify areas where you can optimize inventory & reduce risk

Optional inventory management solutions, spare parts on-demand, and consignment programs help with ongoing spare replacement. These programs allow quick replacement of failed components on the production system to reduce overall downtime.

Benefits

- Downtime mitigation; having the right components on hand when needed mitigates extended production losses due to stockouts

- Capital budget and/or operational cost reductions; reducing the capital required to establish spare parts inventory at startup and beyond

- Parts order convenience; secure, web-based eCommerce storefront and Customer Portal to identify and order parts, and track delivery status

Performance

Performance

Increase the productivity of manufacturing operations by using data to diagnose and resolve issues and drive continuous improvement.

Reliability Assessment

Manufacturing Software

Production Performance Analysis

Production ecosystem overview

ATS Reliability Engineers (RE)s will extract production data and interview stakeholders in production, maintenance, and engineering to gain a comprehensive overview of the production ecosystem.

The RE will provide a risk-based service plan recommendation aligned with your site mission, operations, goals, and KPIs.

Benefits

- Interview stakeholders in production, maintenance, engineering, etc.

- Facilitated by an ATS Reliability Coach

- Risk-based service plan recommendation aligned with your site mission, operations, goals, and KPIs

Illuminate™ Manufacturing Intelligence

Illuminate™ Manufacturing Intelligence is an on-premise real-time production performance monitoring system created by ATS.

Benefits

- Replaces hunches and tribal knowledge with data-driven decisions

- End-to-end solution that includes end-user training and post-integration support

- Meets the need of each unique manufacturing environment, regardless of the types of equipment running, the number of lines or the manufacturing footprint

Performance benchmarking and improvements

Using data from Illuminate™ Manufacturing Intelligence software – a cross functional team comprised of an ATS Reliability Engineer, Asset Subject Matter Experts (SMEs), and Control Specialists proactively monitor machine state, identify root causes of machine faults through visual KPIs, and help manage machine uptime.

Benefits

- Optimize the condition and reliability of high-value production assets

- Drive quantifiable machine improvements

Training

Training

Reinforce training received during integration to improve operation and maintenance practices and maximize return on investment.

Instructor-led Launch Training

Instructor-led Training

eLearning

Smart Coach

Set operations up for success

Formal training program for production and maintenance personnel. Launch training is a mixture of classroom instruction and hands-on practical work designed to maximize knowledge transfer and increase productivity.

Modules include a pre-training skills assessment, equipment troubleshooting, and preventive maintenance.

Benefits

- Lower overtime dependencies

- Improve employee skill level and job satisfaction

- Increase overall job performance

Empower your workforce

Workforce turnover can impact your production. It is important to retrain operators and maintenance staff on how to run and care for your equipment.

Formal training includes a mixture of classroom instruction and hands-on practical work designed to maximize knowledge transfer and increase productivity.

Modules include a pre-training skills assessment, equipment troubleshooting, and preventive maintenance

Benefits

- Increase knowledge retention

- Improve employee skill level and job satisfaction

- Spread equipment service knowledge across more employees to ensure troubleshooting and triaging can be initiated promptly.

High-Speed Automation Specialist (HSAS) Program

Access to the online flexible user-driven training program available 24/7

Content related to basics, controls systems fundamentals, and troubleshooting

Standard introductory training content on ATS standard machines (e.g. SuperTrak, OmniTrak, Vision, and Lasers) also available

Benefits

- Empowers new automation or ATS standard machines operators and technicians

- Consistent and condensed online training program to increase employee retention

- Improve systems performance by enabling the operations team to be more prepared to efficiently operate, maintain and troubleshoot equipment

- Mitigates risks of injury

Smart Coach

The Smart Coach solution is customized to provide training at point of use for operators, maintenance, and engineering personnel. Allowing team members to learn aspects of the machine independently and as needed to become more self-sufficient.

Smart Coach content can include instructional videos, pictures, 3D models, or documents.

Content can be viewed through numerous devices – tablets, smartphones, HMIs, hands-free smart glasses or standard computers.

Benefits

- Improves knowledge transfer

- Empowers workforce and reduces dependency on SMEs

- Available 24/7 via connectivity to a secure cloud-storage repository

Explore our services

The ATS service advantage

- Comprehensive lifecycle service portfolio

- Large, multidisciplinary workforce

- Highly refined processes for testing and optimizing complex automation systems

- Global footprint

- Warranted work

Please complete the form to connect with an ATS service representative.