Minimize Yield Loss: Unlocking Manufacturing Efficiency with High-Quality Process Data

Feb 16, 2024

“Manufacturers invest in minimizing or eliminating the yield loss they experience because at the end of the day every rejected product or lot is simply a loss of dollars. The fiscal impact is different depending on the industry but between the material, time, labor, energy, and opportunity wasted when product produced is discarded the monetary loss experienced is often significant”

– Greg Sullivan, Solutions Architect, ATS Service

Manufacturers keen on operational excellence continually monitor key performance metrics, and one critical metric is yield loss – the percentage of rejected or defective products out of the total production. Elevated yield loss rates can strain a manufacturing operation financially. The strategic collection and analysis of operational data emerge as essential tools for manufacturers to minimize yield loss, boost throughput, and enhance their financial performance.

Why manufacturers should care about yield loss rate

Regardless of the industry, discarded products translate to economic losses for manufacturers. Whether it’s raw material, energy, labor, or opportunity costs, each discarded product during production results in a measurable reduction in economic return. Yield loss also leads to unnecessary wear on equipment and parts, impacting the expected operating lifetime and increasing maintenance costs.

Beyond financial implications, yield losses can affect a manufacturer’s ability to meet production targets, influencing customer relationships and competitiveness. This is particularly critical for contract manufacturers facing penalties for failing to fulfill contractual obligations.

Environmental and societal impacts accompany yield losses, contributing to landfill waste, the release of toxic materials, and resource depletion. Reducing yield loss is not just an economic imperative but also a responsible choice for the planet.

Strategies to reduce yield loss

Once operational data is collected, manufacturers can break down the lost output and discern quality loss versus performance or availability loss. Understanding the root causes of yield loss allows for the development of targeted solutions and data-driven changes to manufacturing processes.

The quality of this analysis hinges on the data’s granularity and reliability. An IoT (Internet of Things) platform proves to be the optimal method for collecting high-quality manufacturing data. It minimizes human error, offers greater storage capacities, and provides access to station and cell-level data that traditional methods lack.

Acquiring high-quality data with Illuminate™ Manufacturing Intelligence

Illuminate™ Manufacturing Intelligence, an Industry 4.0 smart manufacturing system developed by ATS Corporation, exemplifies an IoT platform purpose built to collect and analyze production performance data.

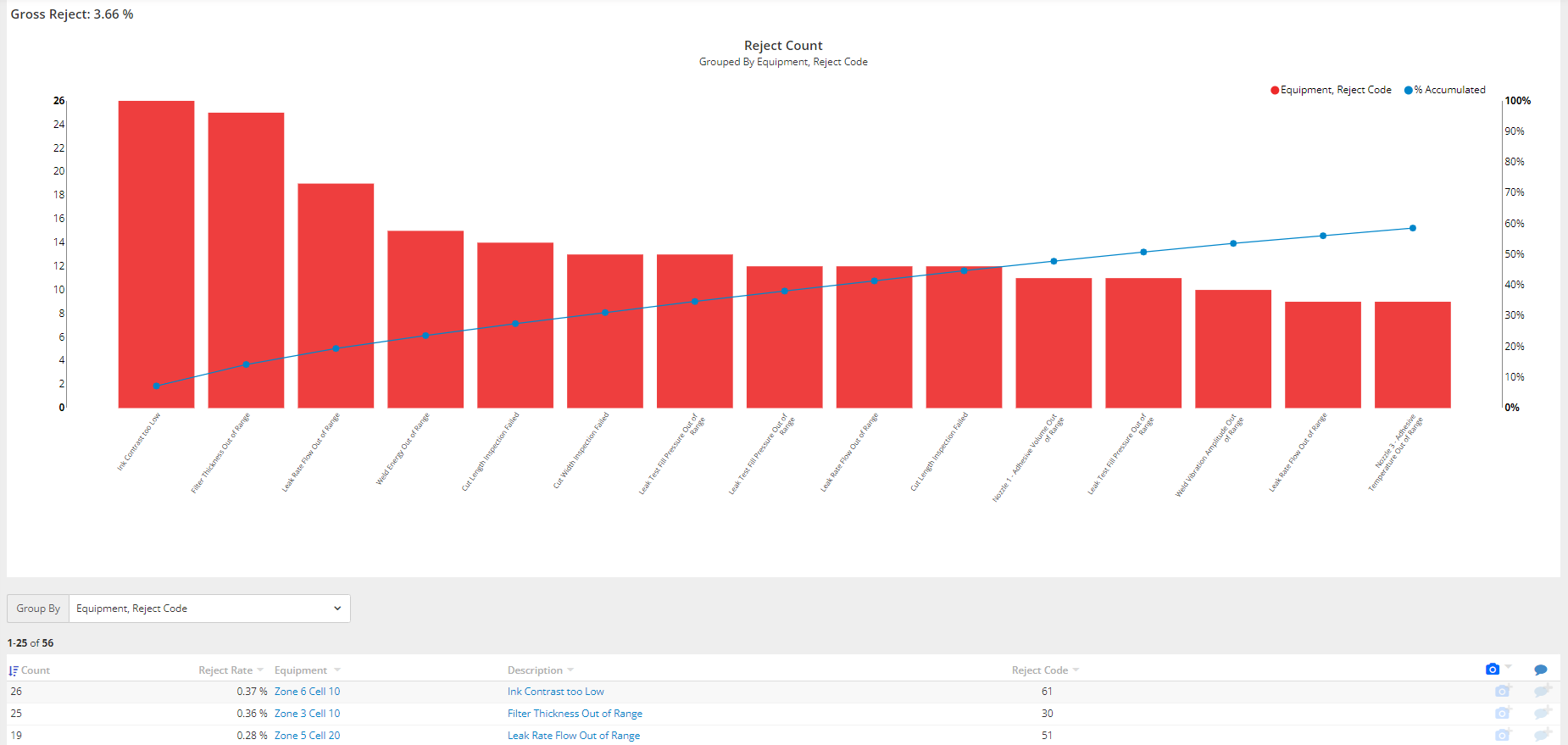

Take the case of a Class II medical device manufacturer facing significant yield losses. Illuminate™ software enabled them to identify and rectify defects in real-time, significantly reducing overall yield loss. The platform’s Reject Summary page displayed valuable information for data-driven decision-making.

The screen capture above displays the Illuminate™ Manufacturing Intelligence Reject Summary page. With the ability to view data from a wide range of time periods, users are provided with a wealth of valuable information attached to every reject experienced enabling data driven decision making.

Closing thoughts

Output loss is a costly affair. Leveraging IoT-enabled solutions like Illuminate™ software empowers manufacturing organizations to collect high-quality, real-time data for effective root-cause analysis and informed changes. Modern tools expedite reporting and facilitate quick, data-driven solutions. Minimizing yield loss opens avenues for maximizing production capacities, eliminating costs, and positively impacting the bottom line.